- Home Page

- Company Profile

-

Our Products

- Circular Bellows

- Metallic Circular Expansion Joints

- Pressure Balance Expansion Joint

- Externally Pressurized Single Expansion Joint

- In line Pressure Balance Expansion Joint

- Pressure Balanced Expansion Joints

- Dual Gimbal Expansion Joint

- Single Expansion Joint

- Externally Pressurized Expansion Joint

- Single Reinforced Expansion Joint

- Toroidal Expansion Joints

- Dual Reinforced Expansion Joints

- Dual Expansion Joint

- Dual Hinge Expansion Joint

- Single Hinge Expansion Joint

- Single Gimbal Expansion Joint

- Dual Tied Expansion Joint

- Inline Pressure Balancing Expansion Joints

- Single Tied Expansion Joint

- Metallic Rectangular or Squire Expansion Joints

- Metallic Thick Wall and Cold Spun Expansion Joints

- Non Metallic Fabric Expansion Joints

- Non Metallic Composite Type Expansion Joints

- Design of Expansion Joint

- Bellow & Expansion Joints Services

- Flexible Hoses

- Pressure Vessels

- Exhaust / Vent Silencer

- Testable Ply Bellows

- Hexagonal Expansion Joint

- Expansion Joints

- Non Metallic Rubber Expansion Joints

- Non Metallic Elastomeric Type Expansion Joints

- Other Products

- Stainless Steel Bellows

- Universal Bellows

- Stainless Steel IBR Approved Bellows For Piping

- CS Testable Ply Bellows For Vibration

- Indiaflex Thick Wall Expansion Joints

- Indiaflex Pressure Balance Bellows

- Indiaflex Rectangular Expansion Bellows

- India Flex Rectangular Bellows

- Square Metallic Bellows

- Oval Bellows

- Fabric Bellows or Non-metallic Bellows

- Pressure Balance Expansion Joints

- Rectangular Metallic Bellows

- Heat Exchanger Bellows

- Contact Us

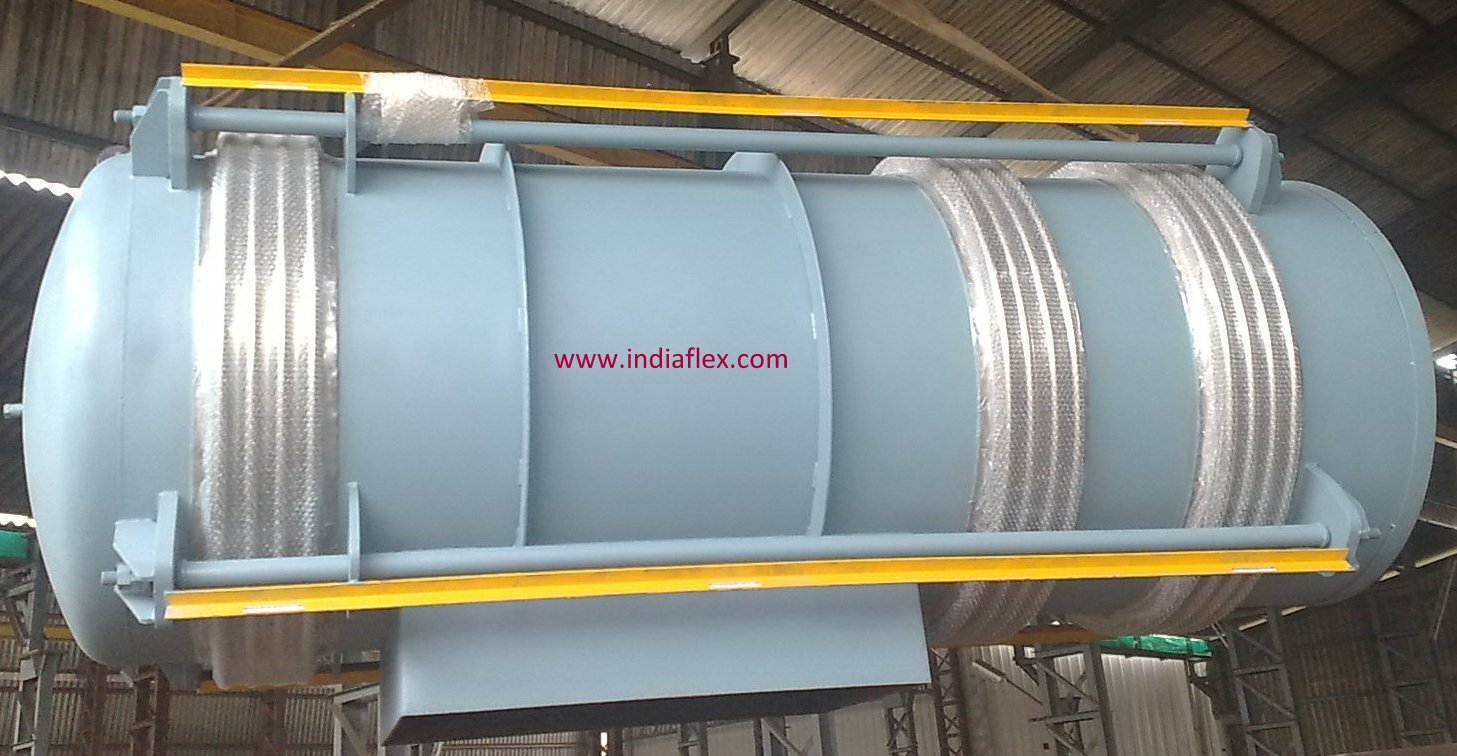

Pressure Balance Expansion Joints

1000000 INR/Unit

Product Details:

- Media Steam, Gas, Oil, Water, Chemicals

- Head Code Round

- Surface Treatment Galvanized / Painted / Polished

- Max. Temperature Up to 700C

- Flange ANSI, DIN, JIS Standard or Customized

- Material

- Technique Bellows Formed and Welded Construction

- Click to View more

X

Pressure Balance Expansion Joints Price And Quantity

- 500000.00 - 100000.00 INR/Unit

- 1000000 INR/Unit

- 1 Unit

Pressure Balance Expansion Joints Product Specifications

- Up to 40 bar

- Pressure Balance Expansion Joint

- ANSI, DIN, JIS Standard or Customized

- Bellows Formed and Welded Construction

- Cylindrical

- Galvanized / Painted / Polished

- Steam, Gas, Oil, Water, Chemicals

- Flange / Welded / Threaded

- Up to 700C

- Round

Pressure Balance Expansion Joints Trade Information

- Cash in Advance (CID)

- All India

Product Description

Features:- Optimum functionality

- Minimum maintenance

- Longer serving life

Functionality:

- Single or double line bellows assembly is connected with the balancing bellows with the help of tie rods or bars. This helps in restraining the axial and compressive thrust that is caused due to internal pressure

- It also allows free lateral movement

Superior Movement Capability

These expansion joints efficiently absorb axial, lateral, and angular movements, maintaining structural integrity within diverse piping systems. Their versatile compensator types-including lateral, universal, single axial, and pressure-balanced-ensure tailored solutions for complex industrial applications, effectively preventing fatigue and damage caused by thermal expansion or contraction.

High Performance in Challenging Environments

Built using premium alloys and advanced bellows forming techniques, these joints deliver exceptional corrosion resistance and durability. The comprehensive leak-proof testing-via hydrostatic and pneumatic procedures-guarantees reliability in demanding environments such as refineries and chemical plants, safeguarding the system against hazardous leaks.

Flexible Installation and Long Service Life

Pressure Balance Expansion Joints can be installed vertically or horizontally, providing flexibility for varied project requirements. Their robust construction and surface treatments-galvanized, painted, or polished-enhance longevity, with a life cycle exceeding 10,000 operational cycles, ensuring minimal maintenance and sustained performance.

FAQ's of Pressure Balance Expansion Joints:

Q: How do pressure balance expansion joints function within a pipeline system?

A: Pressure balance expansion joints are designed to accommodate axial, lateral, and angular movements caused by thermal changes, vibration, or pressure fluctuations. By absorbing these movements, they prevent undue stress on pipes and minimize the risk of leaks or damage, ensuring the reliability of the pipeline network.Q: What materials can be used for manufacturing pressure balance expansion joints?

A: These joints are fabricated from high-quality materials such as stainless steel, carbon steel, Incoloy, Inconel, Hastelloy, and other specialty alloys. The choice of material depends on the specific application requirements, such as corrosion resistance, operating temperature, and the type of media being conveyed.Q: Where are pressure balance expansion joints typically installed?

A: They are utilized in a range of industries, including power plants, chemical facilities, refineries, HVAC systems, and general piping networks. Their adaptability makes them suitable for both horizontal and vertical installation, addressing unique challenges in each environment.Q: What standards and testing processes are followed during manufacturing?

A: Pressure balance expansion joints are engineered in accordance with EJMA, ASME, and BS standards. Each joint undergoes rigorous hydrostatic and pneumatic leak-proof testing to certify safe operation and meet industry compliance before delivery.Q: When should I consider using a custom-sized expansion joint?

A: Custom-sized joints are recommended for projects with unique dimensional, movement, or pressure requirements not covered by standard models. Manufacturers can tailor the joint's size, type, and end connection to ensure optimal performance and compatibility with your specific system.Q: What benefits do these expansion joints offer over standard pipe fittings?

A: Compared to regular fittings, pressure balance expansion joints can accommodate significant thermal and mechanical movements, reduce pipe stress, extend system life, and maintain leak-proof integrity under high temperature and pressure conditions, which is vital for safety and efficiency in critical applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese